Airius has been manufacturing the patented Airius Air Turbine air circulation fans and destratification fans, since 2004. Airius is a large American plastics engineering and manufacturing company and has patented their air delivery methodology to ensure that the air from the fan is able to move long distance using very low amounts of energy. No other fan can perform like an Airius fan despite the existence of cheap copies.

Normal exposed blade fans can move air but not very far, as the air wants to move in a parallel fashion off the blades. They cannot project air in a straight line over significant distance like the Airius air turbines can. Airius fans can put the air where you need it and control where it goes.

In order to ensure the optimum air flow with the lowest amount of energy consumption, Airius combines the world’s leading German fan motors from EBM Papst in 95% of their fan models, with their unique patented air turbine and tapered venturi throat design.

EBM Papst are globally recognised for manufacturing top of the range, highly efficient fan motors. It is our belief that these are the best fan motors in the industry. These motors are available in both 4 pole, 2 pole and EC motor type configurations.

Since first invented in 2003 by EBM Papst, the EC motor type is now the biggest selling fan motor type in the world thanks to its supreme efficiency and very low energy consumption compared to the amount of air they move.

New energy efficiency standards in Europe updated every 5 years, are driving the switch to EC motor use across all fan and related motor types.

The EC nomenclature refers to Electrical Commutation. EC motors use up to 70% less electrical energy than a non-EC fan motor for the same fan output.

The EC motor is certainly Airius’ largest selling fan motor, from both smaller fans up to the largest industrial fans that Airius make, due to the many benefits EC motors have over other fan motor types.

If you look at fan output, the EC motor combined with cutting edge impeller design offers superior air flow and thrust compared to non-EC motor of the same capacity. EC Fan motors offer the most volume and velocity of air flow / per watt.

EC Fans run on an efficiency of between 60-90% whereas other fan motors run at a maximum of 50%.

EC fan motors are essentially a digital fan.

They offer many benefits to the building user and owner compared to a non-EC fan motor including: –

- Efficiency

- Quietness

- Smoother operations for cooling fans

- Longer life

- Smaller and lighter motors

- Ease of install

- Even higher efficiency at lower speeds

- Can receive or send signals to a computer or Building Management System

- Can be controlled by programmable touch screens

- Can be controlled by WI-FI systems

- Allows full monitoring of fan performance

An EC motor has sophisticated electronics built-in for communication, monitoring and responsiveness. Every motor can respond to a range of external signals to independently adjust speed, while they are able to send performance signals to a central control system, triggering warnings before inefficiencies or faults occur. Since they are digitally controlled without physical contact, EC motors also have a longer lifespan than DC motors. They have electronics controlling the stator, and since they do not need to waste power inducing the rotor field, they give better performance and controllability and run cooler than AC induction motors.

For the more technical explanation; –

An EC-drive consists of an EC-Motor where permanent magnets create the required radial magnetic field inside the motor and an EC-controller works as a kind of frequency inverter that creates the current for the motor in the correct format. The motor and controller capability are integrated into the one fan unit.

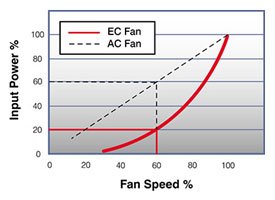

EC motors can effectively maintain part speed with lower power consumption, utilising a computerised soft start, which translates into lower operation costs, fewer maintenance repairs, and shorter payback periods from the initial investment. The motor efficiency changes very little with varying loads. For instance, at the same duty point inverter control techniques can typically absorb 36% more power than EC and similarly Triac control systems consume 118% more.

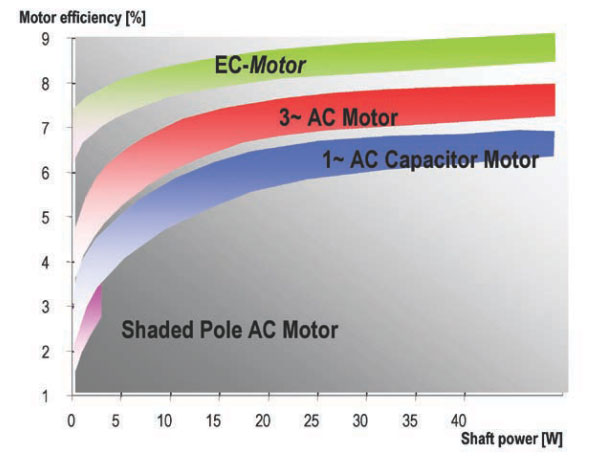

In the chart opposite you can easily see the efficiency difference between EC and AC motors

In the chart opposite you can easily see the efficiency difference between EC and AC motors

Reducing fan speed by 40 percent reduces power by 80 percent, as shown:

The EC motor combines high efficiency DC motors with electrical commutation and integrated speed control.

The EC motor generates its own 0–10-volt power supply for the control component of the fan. This can then be hard connected to controllers, touch screen controllers, BacNET or Modbus RS 485 protocols, BMS units with individual addressing of each fan now possible and of course – full wireless WI-Fi control.

The ability to offer infinite speed control and monitoring of each fan separates the EC motor from other fan motor types.

Normal shaded pole motors can only have their speed adjusted though using either Triac or transformer type controls.

Airius uses only the transformer type controls on those motors as they are a low noise control solution. Triac controllers, which change the waveform of the motor to control it, offer limited speed control range and also contribute noise to the motor at lower speeds as the changing of the wave form in the motor induces frequency changes to the motor thereby increasing motor noise. They can also shorten the life of the motor and it is not possible to get the motor speed down below approximately 30% and the methodology of reduction in speed motor results in excess wear over the longer term.

The EC motor, however, offers infinite speed control with no unnecessary load, meaning you can reduce the RPM down to almost zero and can control the fan accurately and quietly right through the RPM range with no induced speed control motor noise.

Another great benefit of the EC motor is the ability to run on both 50 and 60 HZ power sources without any changes needing to be made to the motor configuration.

This is very helpful in countries where they use 240 volt bt run on 60 HZ, which is different to the Australian power source of 240 volt 50 HZ.

There is no impact on performance when using either 50 or 60HZ.

With shaded pole motors, the change form 60HZ to 50 HZ reduces the power output by around 20%, this means that motors running in a 60HZ power environment provide more air flow than those running in 50 HZ environment.

This chart below if from EBM Papst highlighting the difference in Fan motor efficiencies:

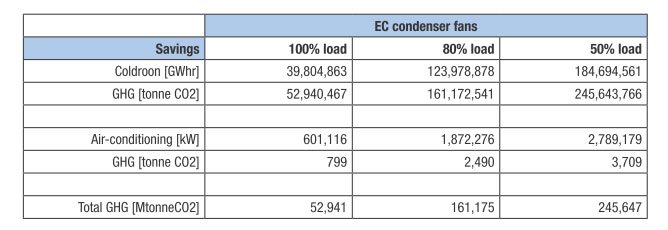

This chart below shows the energy savings achieved by using EC motor fans over a typical shaded pole equivalent fan motor. As can be seen the energy and related carbon savings are significant.

In order to ensure a reliable, highly efficient air flow solution, the EBM past fan motors not only lead the world in EC motor design, they also have the optimum fan blade or impeller design as an outcome of detailed engineering and air flow analysis. The use of EBM Papst EC motors and their leading fan blade design, combined with the unique and patented Airius air flow technology found in all our fan cases, is why Airius fans are the market leader in both air circulation for cooling and destratification.

Airius fans using EBM Papst EC motors provide cooling air flow and winter destratification solutions for a broad range of applications including commercial fans, industrial fans, and retail fans in locations such as: –

- Sports halls

- Gymnasiums

- Warehouses

- Manufacturing plants

- Climbing Gyms

- Breweries,

- Classrooms

- Theatres

- Offices

- Hotels

- Laundries

- Indoor pools

- Sports arenas

- And many more unique applications

Airius fans are also used either in conjunction with Air Conditioning systems to reduce running costs and optimise mixing and distribution or in lieu of air conditioning ductwork at all. The incorporation of an EC motor into those applications offers trouble free communication and control between both systems, and results in significantly reduced running and capital costs for the Air Conditioning components.

With hundreds of thousands of Airius fans sold worldwide into a huge range of commercial facilities, the Airius Air Pear fan solution ensures clients receive a proven, effective and reliable fan solution for whatever their required application.